August 27,2024By:Innova OpticsView:516

Infrared lens is usually made of germanium glass with high refractive index. Germanium glass is only transparent to infrared light, but not to visible light and ultraviolet light. Compared with ordinary lenses, infrared lenses made of special germanium glass can gather light in a longer wavelength range on the same plane, so objects can be seen clearly by infrared imaging during the day or at night. The reserves of germanium metal are not low, but the extraction of high-concentration germanium is very difficult, so the production cost of germanium lens glass is relatively high, and the market price is often higher than that of ordinary lens glass.

The wavelength of visible light in nature ranges from 0.39μm to 0.78μm, and the wavelength of infrared thermal radiation ranges from 0.75μm to 1000μm. As long as the temperature of an object is above the absolute zero value of -273℃, infrared radiation will be generated. Infrared night vision devices detect infrared energy through non-contact, convert it into electrical signals, and then generate thermal images and temperature values on the display. Infrared night vision devices also receive light waves (infrared bands) that are invisible to the human eye.

Visible light is usually used in good light conditions during the day or at night. Although there are many low-light night vision devices now, the imaging effect of low-light night vision devices is not satisfactory at night with poor light. But infrared night vision devices can work around the clock, and at night, it can still image.

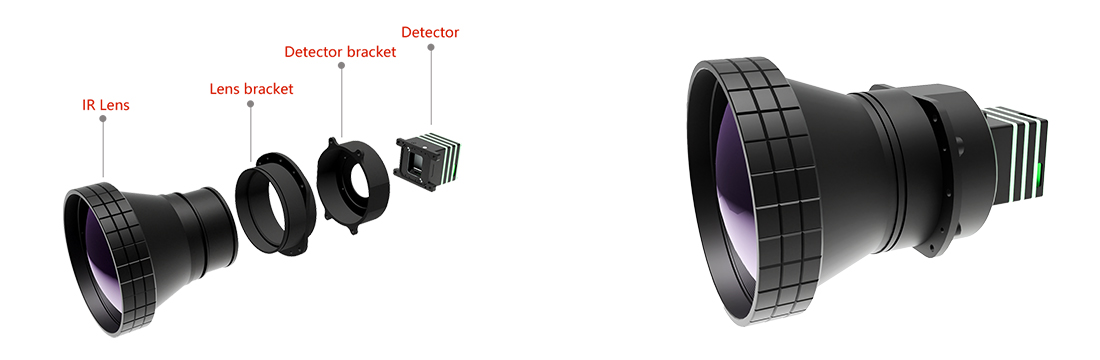

Since most infrared lenses are made of substances such as germanium, chalcogenide glass, or other materials with low absorption in the infrared spectrum, infrared lenses work differently from ordinary visible light lenses. Ordinary lenses function more or less the same as human eyes, receiving radiation in the visible spectrum and converting it into images. Infrared lenses use heat (i.e. infrared rays or thermal radiation) to present images.

Infrared lenses mainly include: electric focus infrared lenses, manual focus infrared lenses, electric continuous zoom infrared lenses, manual/thermal infrared lenses, optical athermal infrared lenses, infrared fixed focus lenses, infrared temperature lenses, and infrared imaging lenses.

First, infrared lenses and ordinary lenses are different in design. Infrared lenses require special materials and coatings to work within the infrared spectrum. These materials and coatings are expensive and require a higher level of technology to manufacture. In contrast, ordinary lenses are relatively simple in design and manufacturing, so the cost is relatively low.

Second, there are differences in market demand between infrared lenses and ordinary lenses. Infrared lenses are usually used in military, security, medical and other fields, and the requirements for lenses are higher, so the demand for infrared lenses is relatively small. Ordinary lenses are well-known to the public, and the demand for ordinary lenses is more extensive. Due to the difference in market demand, the production scale of infrared lenses is relatively small, and the cost is correspondingly high.

In addition, infrared lenses and ordinary lenses are also different in use. Infrared lenses are generally used in specific environments, such as at night or in bad weather, which requires higher stability and durability of infrared lenses. Therefore, infrared lenses usually use stronger materials and more stringent manufacturing processes, which also leads to higher prices.

In general, the high price of infrared lenses is mainly due to the high technical and material costs in their design and manufacturing, relatively small market demand, and special requirements in use. Compared with ordinary lenses, infrared lenses are different in many aspects, so their prices are relatively high. However, for users with special needs, choosing a high-quality infrared lens is very important.

Go Top