February 02,2024By:Innova OpticsView:484

Fluke infrared lenses allow you to inspect targets that are difficult to inspect with standard infrared lenses due to their size and distance.

Fluke's Professional Series and Expert Series thermal imaging cameras come with the following add-on lenses: The lenses for the TiX560, TiX520, Ti400, Ti300 and Ti200 thermal imaging cameras are smart lenses, which means they do not need to be customized for a specific camera. Calibrated and interoperable between compatible thermal imaging cameras. This way, users can avoid the hassle of sending the camera off for calibration to fit the lens, and can share a lens between multiple thermal imaging cameras. †The glass optics of all Fluke IR lenses are 100% constructed from specially coated diamond-turned germanium, the material that delivers the most efficient energy transfer to the detector ever.

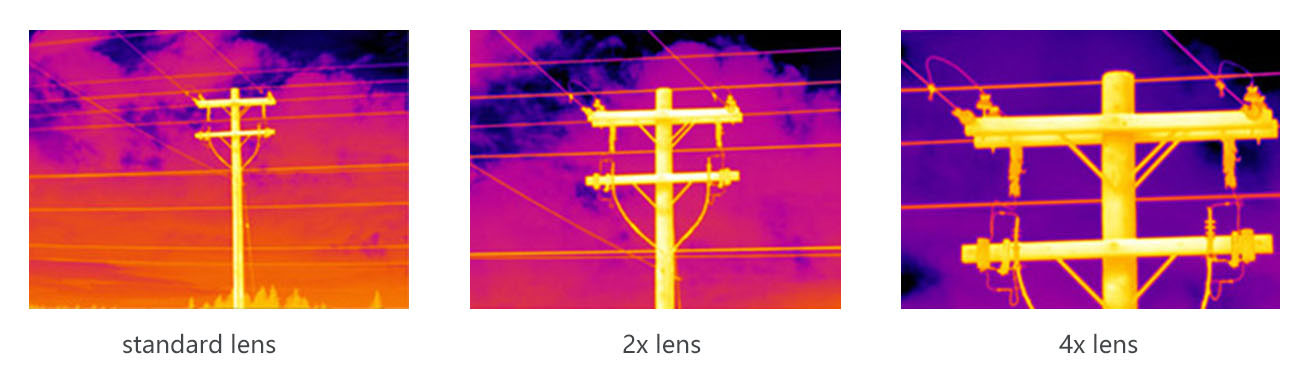

Telephoto lens

Magnifies targets 2x or 4x compared to standard lenses, allowing users to see more detail.

When performing maintenance inspections, electrical inspections and process inspections, the 2x telephoto lens allows users to capture critical infrared image details to understand possible equipment problems without having to enter hazardous areas or climb very high ladders.

For the petrochemical, power and metal smelting industries, the 4x telephoto lens helps users identify subtle and distant potential problems, such as faulty joints on high-voltage power lines, or overheating refractory materials on tall flare towers.

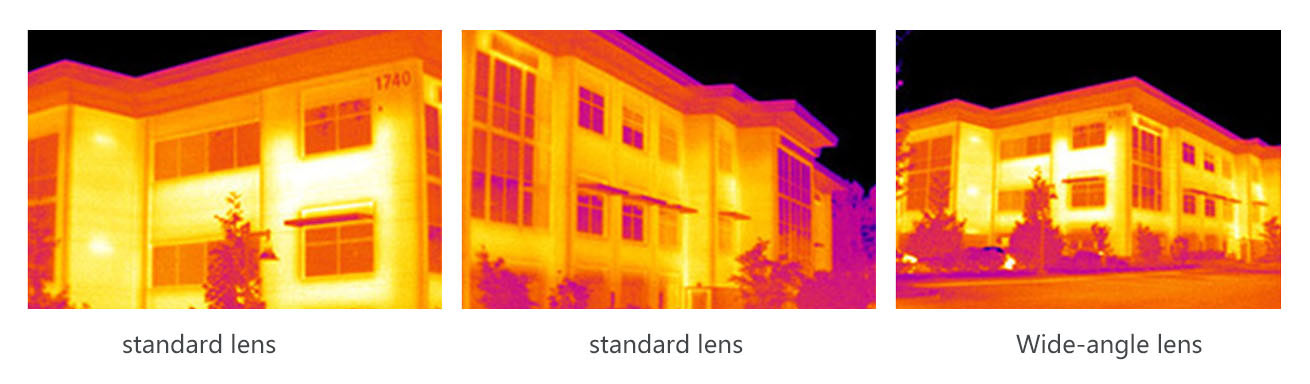

Wide-angle lens

When working in tight spaces, use a wide-angle lens to get a closer look at larger targets.

For electrical inspections, use a wide-angle lens to see an entire row of switchgear in a tight space, or an infrared window for a wider view.

For building diagnosis, roof inspections and plant inspections, using a wide-angle lens can save time by allowing you to see a much larger area at the same time.

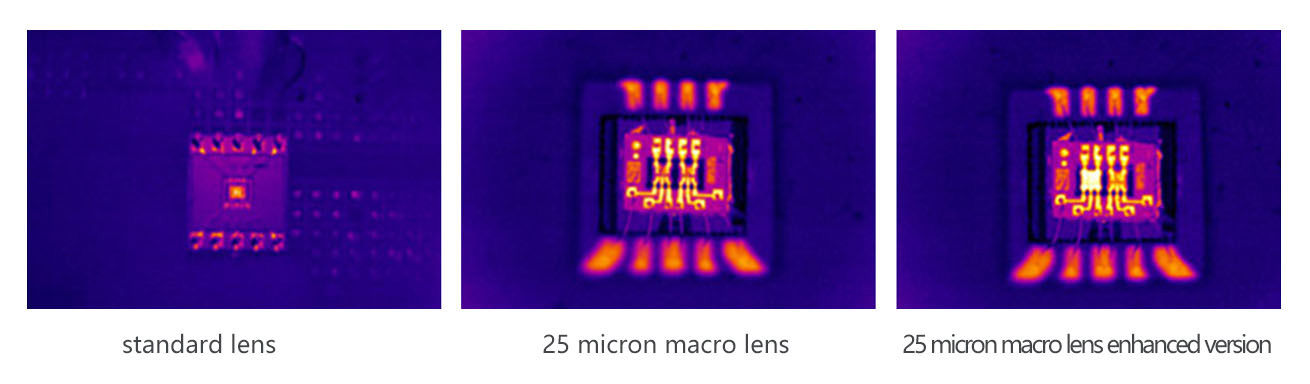

Macro lens

Get incredibly clear images of extremely small objects, down to 25 microns, which is smaller than the average human hair.

When conducting research and development, use a standard lens to understand how thermal patterns affect the properties and performance of materials.

For electronics design and verification, use standard lenses to gain insight into heat build-up and dissipation on printed circuit boards, identify faulty or undersized parts, and even pinpoint the location of faults on those parts.

Determine which thermal imaging camera and lens combination is best for your application based on the distance to the target and the size of the location you want to observe.

Go Top